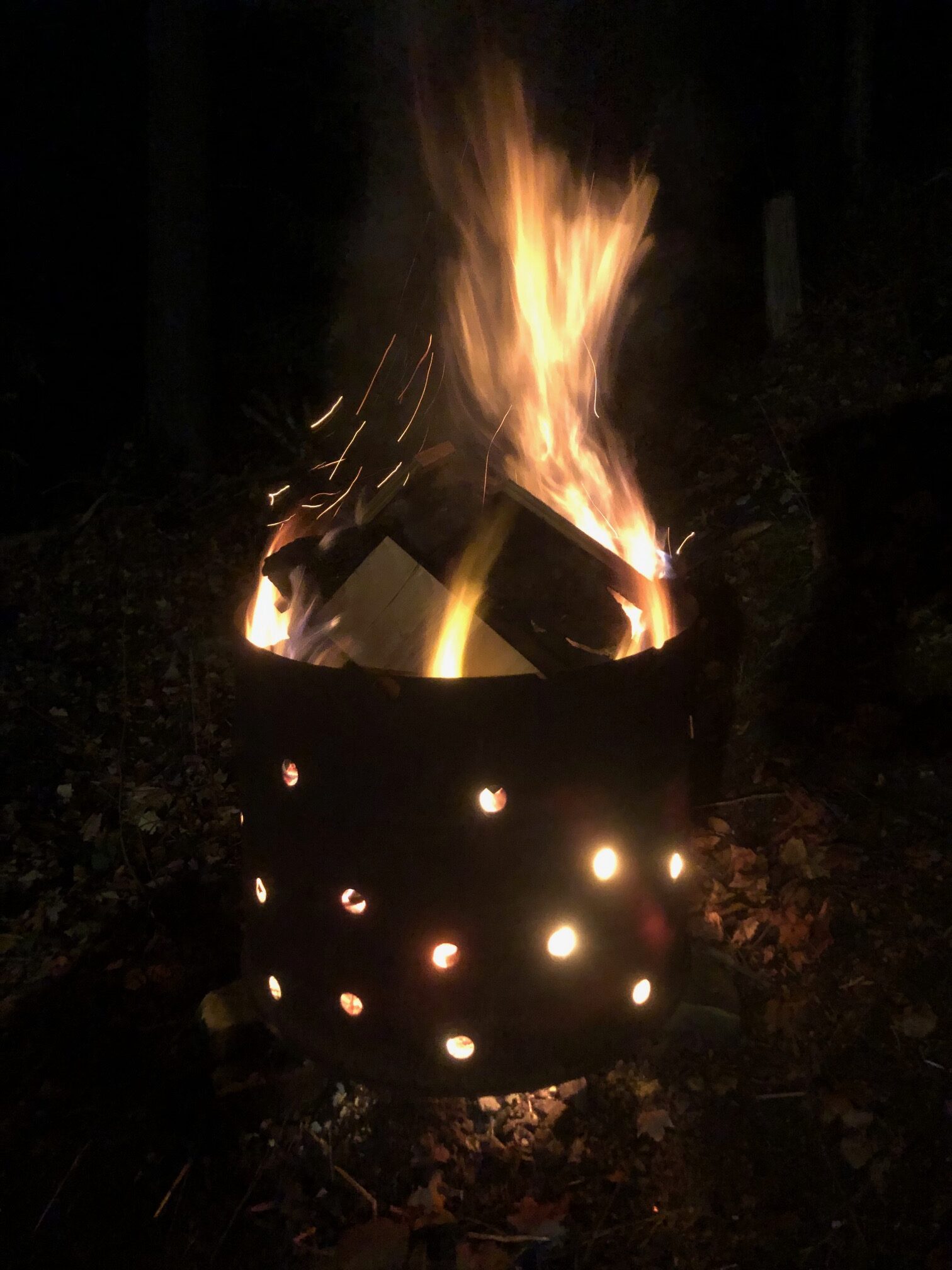

This page documents the process of a very special commission. A community approached me and asked if I could make an object to commemorate a person of importance who had passed. The hope was to use his cremation ashes in the process of making the object. We decided a bowl would be a fitting object. I would smelt iron, add the ashes to the furnace during the smelt, and forge the resulting iron into the bowl, which would then be used in ritual as part of their spiritual practices. I was honored to work on such a project, and although I never met the man, the process of using the ashes in the process was humbling. One of the reasons I smelt iron is the connection to people and traditions of the past. There are theories that people in the past have added the remains of humans and animals to the iron smelting process to imbue the power of that individual into the object (Hedeager, 2011; Goldhahn & Oestigaard, 2008; Gansum 2006). By following this process I am connected the people who may have performed these rituals in the past, and if one chooses to believe: the object will then be imbued.

10/28/23 Ore roasted in preparation for smelt. 90lb of ore from Forest Dale, VT will be used. 120lb charcoal chopped to size. I made a last minute decision to add 8% manganese ore in hopes of increasing yield. Photos show ore roast, Forest Dale limonite (roasted), and Johnstown, PA manganese ore. (I later discovered through working with a local university that what I thought was manganese ore, was actually high grade specular hematite).

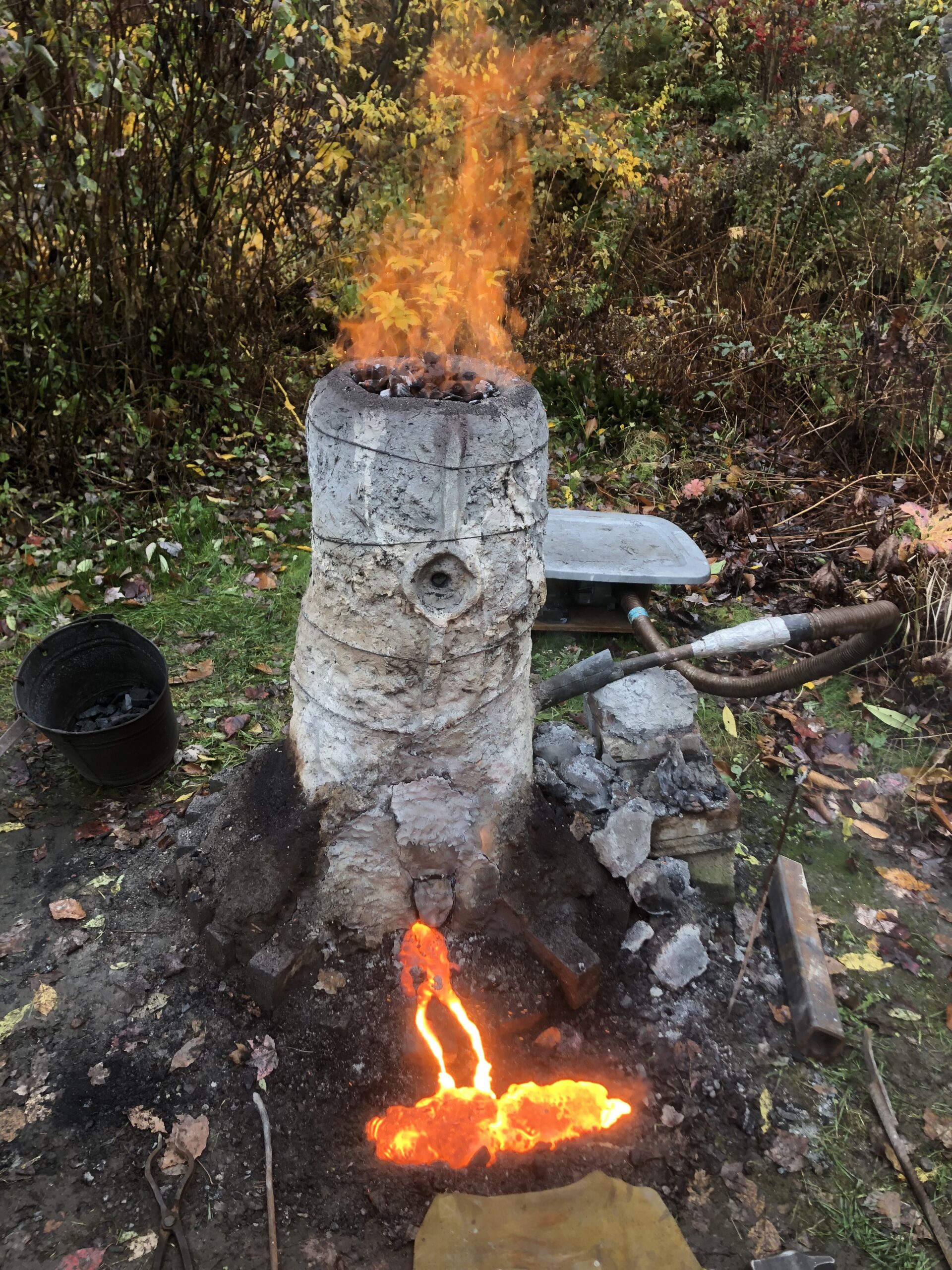

10/29/23 First bloomery smelt in ‘cyclops’ furnace. Smelt began around 12:30pm on a rainy day. Smelt started out as usual. Offerings were made to the furnace in the first charge (as shown: ashes, iron ore, manganese ore, small piece of high quality Irish ore, mushroom). Ashes were added at important moments during the smelt: first charge, opening tap arch, final charge, as well as a few other moments during the smelt. The weight of ashes added was judged by “feeling” and was not weighed or otherwise measured. Manganese ore was added at first charge and then not again until tap arch was opened. Initial slag was abundant and slightly viscous, but continued to improve. Fractured slag color was darker than usual indicating a lower than normal metallic quantity edging toward fayallite. I’m guessing this is the work of the manganese taking the place of Fe in the 2FeOSio4. At around charge 14 I realized there was a gap in front of the forming bloom and charcoal was able to freely fall down past bloom. I believe slag was also draining of the top of the bloom resulting in an unprotected top surface, which in turn I believe would have led to the air blast re-oxidizing the bloom and cutting it’s way in. This was confirmed when the bloom was extracted and was a donut shape with very little material in the center. The slag condition continued to degrade as the smelt went on and I eventually discontinued the addition of manganese (a total of approximately 6.5lb was added) and lessened the amount of ashes that were added. Nik and Trey showed up at the end of the smelt. Bloom “birthing” was easier than I anticipated given the quantity of slag that had built up below the bloom. Nik, Liza, Daniel, and I worked the bloom briefly until I realized the poor quality and made the decision to cease hammering. We made a final offering to the furnace, resulting bloom, and Bacchus by drinking some of Bacchus’ “last bottle of mead” and pouring some on the bloom.

The resulting bloom was usable, though smaller than it could have been and very poor consolidation. I still need to weigh and take photos of the bloom, but based on the hammering process I can tell that there is plenty of iron made that can be resmelted in the Evanstad furnace to consolidate and purify. I consider this smelt a success in that iron was made with the addition of Bacchus’ ashes and I have learned what changes will be made to improve the next smelt. Next will be another full bloomery smelt as well as a resmelt of this particular bloom.

11/5/23 Second smelt today. 95lb Forest Dale Limonite, 4lb gromps from previous smelt, cremation ashes added in small quantities through-out the entire smelt. Manganese ore was excluded this time. I patched the eaten away interior of the furnace prior to smelting and put it back into proper dimension (averaging 9” I.D). I made the tap arch shorter (9”). I adjusted the air and aimed for an average of 12 minute charge times, which I succeeded at keeping close to throughout the smelt. The resulting bloom was very successful. 24lb total and very dense. The slag characteristics couldn’t have been better. I added extra ashes toward the end of the smelt to help protect the top of the bloom from the blast as I wasn’t seeing much slag through the tuyere using a probe. This seemed to work quite well. The bloom was cut in half while hot.

March, 2024: First bloom (donut shaped) was remelted in secondary furnace to consolidate and increase the carbon content. This process takes a “failed” bloom that is more or less unforgeable and turns it into a piece of solid iron that can be worked. Two “pucks” were made from the bloom, each approximately 4lbs. The carbon content was increased significantly in each.

April, 2024

A bowl is the decided upon memorial object for this project.

Here I am forging test pieces to figure out the best way to make a bowl from a half-bloom. I forged this under the power hammer using top tools to spread radially. This is very promising. I will either leave the “defects” around the edge to create a bowl with a more organic look, or try and forge weld them shut with other, smaller, pieces of bloom. The plate will then be formed in a carved out stump to raise into a bowl shape. This test piece is currently 10” diameter and about 3/16” thick. I’d like to go large in diameter, but I think the thickness is about right.

9/13/24

Forging the 14lb bloom half to create the bowl. First the half is consolidated, and then it is drawn out on the power hammer, folded, and welded. I will repeat this cycle one or two more times to ensure my iron is solid enough to begin forging thin into a bowl shape. It is then forged under the power hammer into a cube. The edges are then forged and the billet is brought to a cylindrical shape before being forged flat into a round plate. At a certain thickness it becomes too difficult to forge simply by flattening with the hammer dies, so fullers are used to stretch the material out to the desired thickness, in this case about 3/16”. This plate is then refined by hand and dished in a negative shape carved into an oak stump.